Sunscreen is not only a skin protection product but also a key factor in the current cosmetics industry, this is considered an extremely essential cosmetic line in the skin care cycle. With increasing demand, investing in sunscreen products not only brings profits but also helps businesses enhance brand value. At Shizencos, we have a complete sunscreen processing service from formula research to production and testing according to international standards. If you are a cosmetics business and want to understand more about this processing activity, check out the article below!

1. What is sunscreen processing?

Sunscreen is a specialized skin care product that functions to create a protective layer for the skin against the harmful effects of ultraviolet rays (UV rays) from sunlight. UV rays include two main types: UVA (which causes aging, reduces skin elasticity) and UVB (which causes sunburn, dark spots and damage to the epidermis). Using sunscreen daily not only helps prevent skin problems such as dark spots, melasma, wrinkles but also plays an important role in preventing the risk of skin cancer. In addition, many modern sunscreens also integrate moisturizing, oil-controlling, anti-pollution and skin-tone-enhancing ingredients, meeting comprehensive beauty needs.

Sunscreen processing is The process of manufacturing sunscreen products according to the requirements of businesses or cosmetic brands, based on existing formulas or newly developed ones. Through the form of outsourcing, businesses can save time, research and production costs, while ensuring product quality meets standards.

2. Benefits of choosing sunscreen manufacturing

Choose form sunscreen processing will help businesses save costs and production time. This is considered an optimal solution, allowing businesses to focus on their marketing strategy and brand building, without having to invest in complex production systems.

✅ Save costs on factory investment and operating personnel

✅ Take advantage of highly specialized resources from the R&D team

✅ Increase competitiveness thanks to unique formula and exclusive packaging design

✅ Sản phẩm chất lượng đáp ứng tiêu chuẩn kiểm nghiệm

✅ Support all legal documents, product declaration and quality inspection

3. Sunscreen processing at Shizencos

At Shizencos, we provide a complete sunscreen manufacturing service – from formula research, raw material selection, GMP production to legal support and packaging design. With a team of experienced experts and modern technology, Shizencos is committed to providing high-quality sunscreen products that are in line with market trends, helping your brand build reputation and sustainable competitiveness.

3.1 Diverse sunscreen formulas

One of the key factors that differentiates and makes sunscreen products competitive in the market is the formula. Understanding this, Shizencos focuses on researching and developing a variety of formulas to meet modern skin care trends as well as the specific needs of each target customer group. From the characteristics of each skin type to the requirements for protection and aesthetics, we provide optimal options, helping businesses easily shape products with their own brand identity.

Shizencos develops a variety of sunscreen formulas, from physical, chemical to hybrid, to meet the needs of effective skin protection while still being suitable for each skin type and market segment:

- Physical sunscreen: Works by creating a UV reflective film, suitable for sensitive skin.

- Chemical sunscreen: Works based on the mechanism of absorbing and penetrating UV rays, thereby converting them into light or heat with wavelengths that are harmless to the skin..

- Combination sunscreen: The formula combines the advantages of both mechanisms physics and chemistry create a comprehensive and effective sunscreen product to protect the skin.

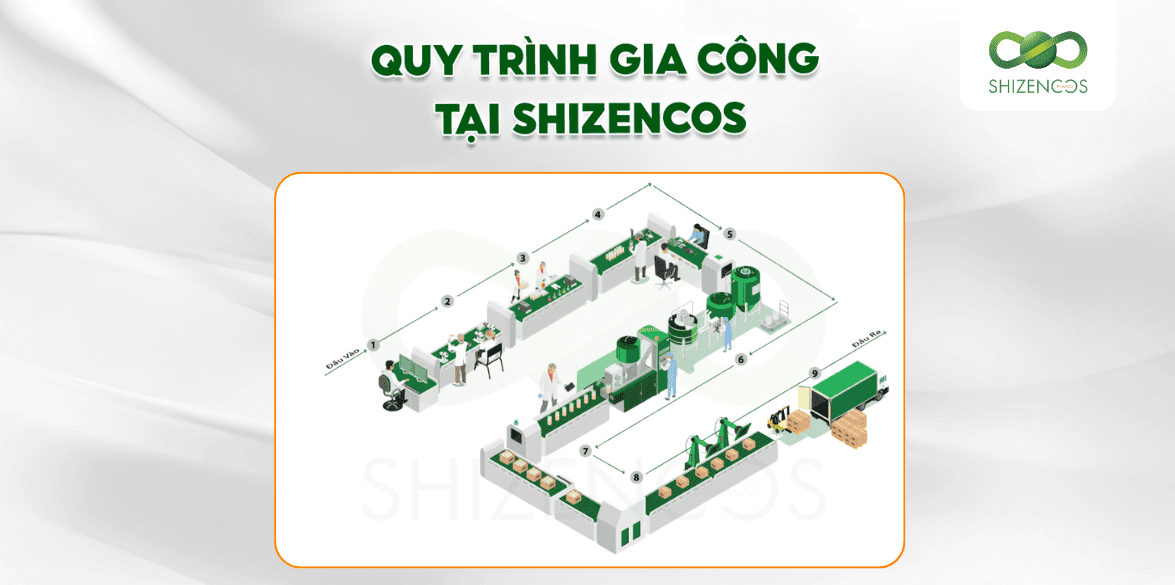

3.2 Sunscreen manufacturing process at Shizencos

Not only providing quality formulas, Shizencos also optimizes the entire production process from idea to final product, helping businesses save time, optimize costs and minimize risks, ensuring the highest quality products. Below are the 9 main steps in the sunscreen manufacturing process at Shizencos:

Step 1: Contact for consultation – Listen to requests and advise on appropriate formulas.

Step 2: Research and Development – R&D team researches and develops optimal formulas.

Step 3: Send samples and adjust – Provide samples, adjust based on feedback.

Step 4: Finalize sample and quote – Confirm final formula, calculate cost

Step 5: Signing contract and cooperation – Both parties agree and sign the processing contract.

Step 6: Prepare ingredients and stir the tank – – Import and check the quality of input materials.

Step 7: Mass production – Put into production according to GMP standards.

Step 8: Product packaging – Filling, sealing, labeling according to design.

Step 9: Delivery and post-production support – On-time delivery, legal support and business strategy.

Shizencos is committed to providing high quality products, helping businesses launch to the market quickly! With meticulous, transparent investment and dedicated service from A to Z, Shizencos is not only a manufacturer but also a reliable companion in the journey of building and developing your cosmetic brand.

Conclude

Sunscreen manufacturing is a smart move for modern cosmetic businesses – both economical and professional. With advantages in technology, scale and highly specialized team, Shizencos is ready to accompany you to create quality, innovative sunscreen lines with your own brand mark.

Contact hệ Contact Shizencos today for a free consultation and start your journey to bring your products to consumers!

There are no reviews yet.